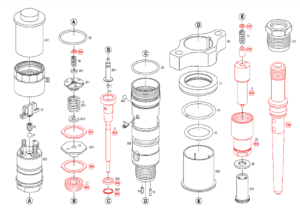

Common rail injectors are key components in modern diesel engines, directly affecting engine performance, fuel consumption, and emissions. Proper maintenance ensures injectors operate reliably and engines run smoothly. This guide covers first- and second-generation commercial vehicle injectors (CRIN1 and CRIN2), passenger vehicle injectors (CRI), and testing procedures.

I. First-Generation Commercial Vehicle Injectors (CRIN1)

Common Models: Cummins 0 445 120 007/121/122/123; Komatsu Excavator 0 445 120 059/123; Mitsubishi 6M70 Engine 0 445 120 006; Iveco 0 445 120 002; Dongfeng Renault 0 445 120 084/085.

Before Replacing Valve Assembly

- Follow disassemble first, then measure. Some injectors only need calibration.

- Remove the solenoid valve and measure:

- Armature lift: 45–50 μm

- Total armature stroke: 85–95 μm

- Residual gap: 35–55 μm

- Measure nozzle needle lift (depends on engine power).

- If deviations are small, replacement is sufficient.

After Replacing Valve Assembly

- Measure nozzle needle lift → determine needle valve shim thickness.

- Measure total armature stroke → select retaining clip thickness.

- Measure armature lift → determine lower hex shim thickness.

- Measure residual gap → determine upper hex shim thickness.

After Assembly

- Pre-injection abnormality → adjust solenoid spring force shim

- Idle abnormality → adjust needle valve spring force shim

Key Shims and Clip Specs:

| Part | Thickness (mm) | Step (mm) |

|---|---|---|

| Armature lift shim B12 | 0.85–1.20 | 0.01 |

| Residual gap shim B11 | 0.90–1.56 | 0.01 |

| Nozzle lift shim B16 | 0.91–1.40 | 0.01 |

| Needle spring force shim B14 | 1.10-2.20 | 0.01 |

| Solenoid spring force shim B13 | 1.20-1.80 | 0.01 |

| Total armature stroke clip B37 | 1.15–1.26 | 0.01 |

II. Second-Generation Commercial Vehicle Injectors (CRIN2)

Common Models: Xichai 0445120081/078/215; Weichai 0445120086/170/169/149/159/213/214/224/265; Yuchai 110; Cummins 0445120289.

Before Replacing Valve Assembly

- Follow measure first, then disassemble. Some valves may still be usable.

- Remove heat shield and solenoid, take out springs and shims, reinstall solenoid, then measure:

- Armature lift: 45–50 μm

- Lift: 35–50 μm

- Solenoid residual gap: 35–55 μm

- Measure nozzle needle lift simultaneously.

After Replacing Valve Assembly

- Measure nozzle needle lift → select shim thickness (engine power).

- Measure lift → select lift shim.

- Measure armature lift → select armature lift shim.

- Confirm solenoid residual gap.

After Assembly

- Pre-injection abnormality → adjust solenoid shim thickness

- Idle abnormality → adjust needle valve spring force shim

Key Shims Specs:

| Part | Thickness (mm) | Sizes | Step (mm) |

|---|---|---|---|

| Armature lift shim B26 | 1.10–1.72 | 0.01 | |

| Over-lift shim B22 | 0.88–1.30 | 0.01 | |

| Nozzle needle lift shim B16 | 0.91–1.40 | 0.01 | |

| Needle spring force shim B14 | 1.10-2.20 | – | 0.01 |

| Solenoid spring force shim B13 | 1.20-1.80 | – | 0.01 |

III. Passenger Vehicle Injectors (CRI Type)

Common Models: 0 445 110***, typically for 4-cylinder engines.

Before Replacing Valve Assembly

- Follow measure first, then disassemble.

- Remove solenoid and measure:

- Armature lift: 40–45 μm

- Total armature stroke: 55–70 μm

- Solenoid residual gap: 35–55 μm

- Measure nozzle needle lift.

After Replacing Valve Assembly

- Measure nozzle needle lift (engine power dependent).

- Measure total armature stroke → retaining clip thickness.

- Measure armature lift → armature lift shim.

- Measure solenoid residual gap → residual gap shim.

After Assembly

- Adjust shims if pre-injection or idle issues occur.

Key Shims and Clip Specs:

| Part | Thickness (mm) | Step (mm) |

|---|---|---|

| Armature stroke shim B31 | 1.18–1.50 | 0.01 |

| Residual gap shim B25 | 0.86-1.70 | 0.01 |

| Total armature stroke clip | 1.155–1.265 | 0.01 |

| Solenoid spring force shim B13 | 1.20-1.80 | 0.01 |

| Nozzle spring force shim B14 | 1.10-2.20 | 0.01 |

Note: For Denso injectors, only armature lift is adjustable (45–55 μm); other strokes are factory preset.

IV. Injector Testing and Engine Impact

- Leak Test (LEAK TEST)

- Ensures sealing of valve assembly, high-pressure O-rings, and nozzle cap.

- Excess leakage → unstable oil pressure, higher fuel consumption.

- Maximum Injection Volume (VL)

- Too high → smoke, fuel increase

- Too low → low power, slow acceleration

- Injector deviation ≤ 6 mm³/h (adjust via nozzle lift).

- Medium-Speed / Emission Test (TL/EM)

- Checks injection characteristics, prevents smoke and emission violations.

- Controlled by nozzle spring force, armature stroke, over-lift shim, solenoid spring force shim.

- Idle Injection (LL)

- Too high → idle smoke

- Too low → stalling, hard start

- Uniformity ≤ 2 mm³/h

- Pre-Injection (VE)

- Too high → knocking, smoke

- Too low → noise, weak start, poor acceleration

- Uniformity ≤ 0.5 mm³/h; adjust via solenoid spring force shim.

Injector Type Measurement / Adjustment Standard Value Shim / Clip Thickness Range (mm) Tolerance (mm) CRIN1 (1st Gen Commercial) Armature lift 45–50 μm B12 0.85–1.20 0.01 Total armature stroke 85–95 μm B37 1.15–1.26 0.01 Residual gap 35–55 μm B11 0.90–1.56 0.01 Nozzle lift Depends on engine B16 0.91–1.40 0.01 Nozzle needle spring force – B14 1.10-2.20 0.01 Solenoid spring force – B13 1.20-1.80 0.01 CRIN2 (2nd Gen Commercial) Armature lift 45–50 μm B26

1.10–1.720.01 Over-lift 35–50 μm B22 0.88–1.30 0.01 Nozzle needle lift Depends on engine B16 0.91–1.40 0.01 Nozzle needle spring force – B14 1.10-2.20 0.01 Solenoid spring force – B13 1.20-1.80 0.01 CRI (Passenger Vehicles) Armature lift 40–45 μm B31 1.18–1.50 0.01 Total armature stroke 55–70 μm Clip 1.155–1.265 0.01 Residual gap 35–55 μm B25 0.86-1.70 0.01 Nozzle needle lift Depends on engine B15 8.30-8.60 0.01 Nozzle spring force – B14 1.10-2.20 0.01 Solenoid spring force – B13 1.20-1.80 0.01 Denso Electric Injectors Armature lift 45–55 μm – – – Other stroke parameters Factory preset – – –

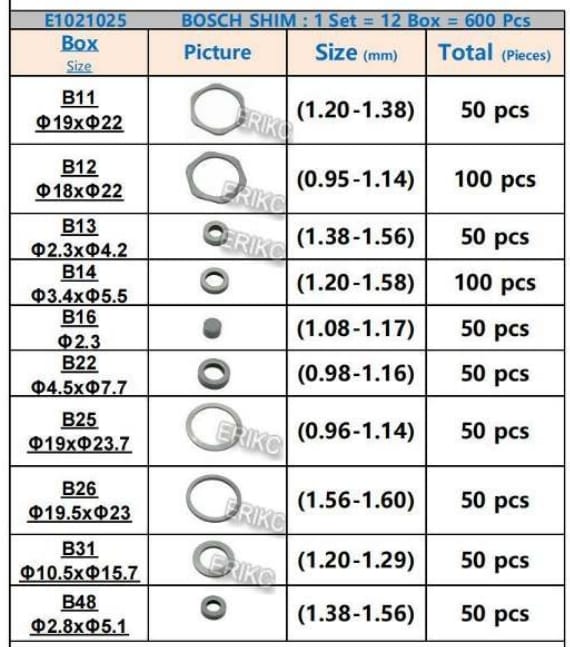

Important: All adjustments require stroke parameters within standard range. Use Bosch or ERIKC original shims for reliable maintenance.

BOSCH CRI CRIN Injector Adjusting Shim Kit 600pcs | Diesel Injector Calibration Shims

600-piece set of high-precision adjusting shims for BOSCH CRI and CRIN diesel injectors—ideal for injector repair and calibration.

DENSO Injector Shim Kit E1022006 | Includes B21 B23 B24 B27 Shims | 400pcs Set

Complete shim kit for DENSO injectors (E1022006), includes B21, B23, B24, and B27 types. 400 pieces total. Custom thickness available.