What Causes a Cummins Engine to Stall While Throttling?

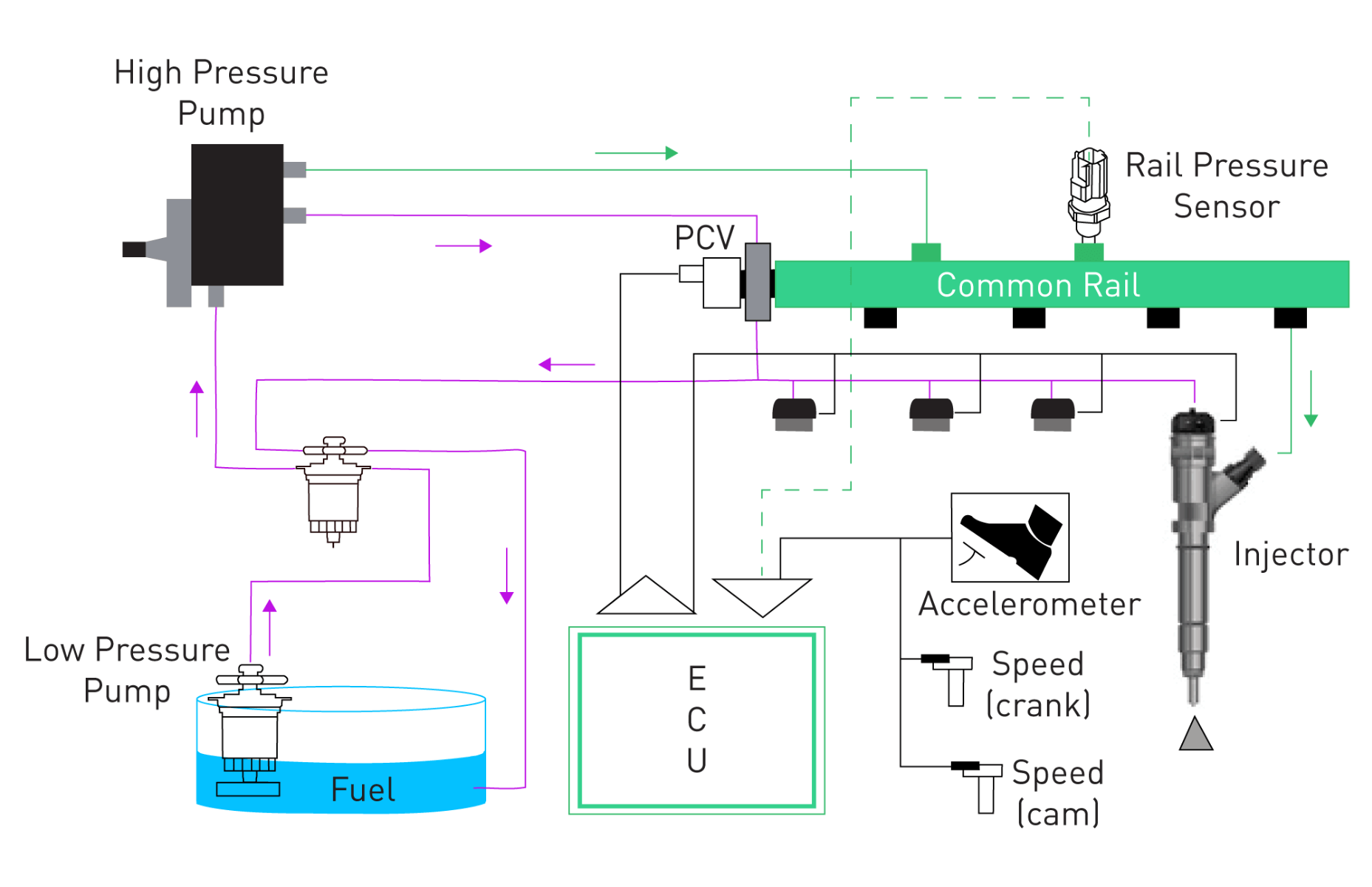

Discover the causes and solutions for a Cummins engine stalling gradually under throttle. This comprehensive guide covers potential issues such as insufficient fuel, clogged filters, air ingress, or a faulty fuel pump. Step-by-step instructions on diagnosing and resolving fuel supply problems, along with preventive maintenance tips, ensure your engine runs efficiently. Ideal for diesel engine users looking to address performance issues and avoid costly repairs.