Introduction

Idle performance is critical for vehicle stability and driver experience. However, problems like unstable idling, excessively high or low idle speeds, and rough engine operation are not uncommon in vehicles equipped with electronic fuel injection (EFI) systems. Unlike carbureted engines, EFI systems are more complex, making diagnosing idle problems more challenging. This article provides an in-depth analysis of common idle issues in EFI engines, focusing on L-type systems, to help you identify and address these challenges effectively.

Causes of Idle Problems in EFI Engines

1. Idle Switch Signal Circuit Issues

EFI engine control units (ECUs) rely on the idle switch signal (IDL terminal) to determine whether the engine is idling. When the idle contact closes, it sends a low-voltage signal to the ECU, triggering the idle control program. Faults like improper contact gap adjustment, poor connections, switch damage, or circuit malfunctions can prevent the ECU from accurately identifying the idle condition. This misinterpretation leads to erratic idle behavior. Addressing these issues should be a priority during diagnostics.

2. Idle Speed Control (ISC) Valve and Circuit Malfunctions

The ISC valve regulates the air bypassing the throttle to stabilize idle speed. The ECU uses input from sensors, such as the coolant temperature sensor and accessory status signals (e.g., air conditioning or power steering), to control the ISC valve. Common ISC valve issues include:

- Carbon deposits clogging the valve.

- Valve sticking.

- Circuit faults like short circuits or open circuits.

A malfunctioning ISC valve prevents the ECU from adjusting the valve’s opening properly, resulting in idle instability. Diagnosing ISC valve issues involves thorough cleaning and circuit inspection.

3. Airflow Meter Problems

The airflow meter measures incoming air volume, which the ECU uses to calculate fuel injection. Faults in the meter or its circuit may distort this data, leading to incorrect fuel-air mixture ratios. Symptoms include:

- Engine misfiring.

- Overly rich or lean mixtures.

Diagnose airflow meter issues by comparing voltage readings at idle with manufacturer specifications using a digital multimeter.

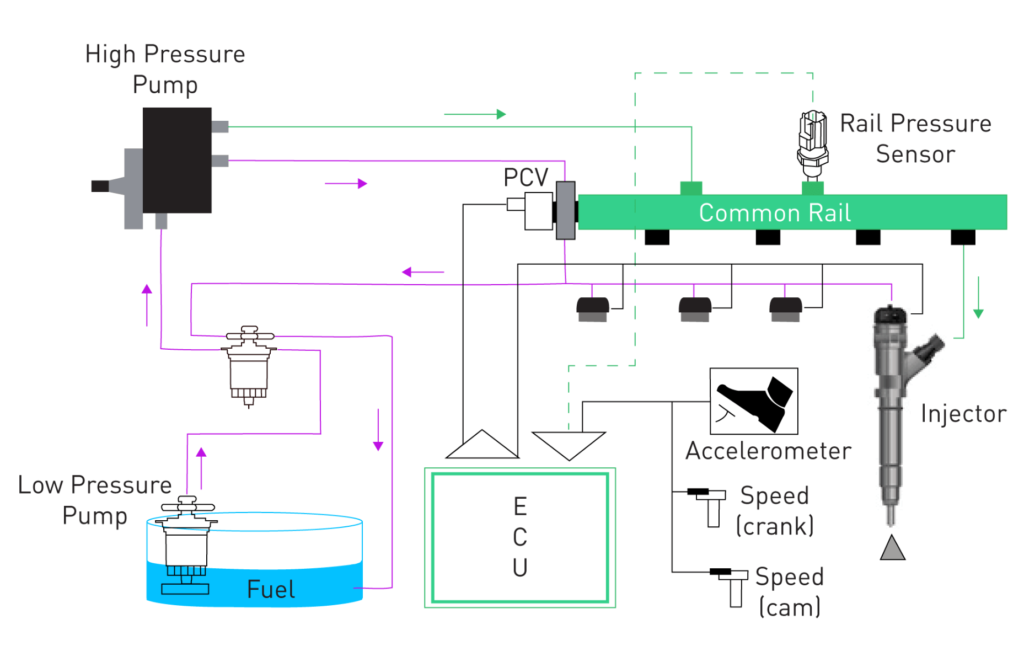

4. Injector and Circuit Failures

Injectors are critical for delivering fuel in precise amounts and patterns. Common injector-related issues include:

- Carbon buildup causing blockages.

- Wear-induced over-injection or leakage.

- Electrical malfunctions in the control circuit (e.g., poor connections, short circuits).

Such issues lead to uneven idle, misfires, or even stalling. Injector cleaning or replacement is often necessary to resolve these problems.

5. Coolant Temperature Sensor Faults

The coolant temperature sensor (CTS) provides data on engine temperature to the ECU, which adjusts fuel delivery accordingly. For example:

- Cold engines require richer fuel mixtures for smooth operation.

- Faulty CTS outputs distorted signals, causing incorrect adjustments.

Diagnose CTS issues by comparing sensor output against expected values under various temperature conditions.

6. Fuel Pump and Fuel System Malfunctions

The fuel pump and associated components maintain optimal fuel pressure. Deviations in pressure affect injector performance, leading to idle problems. Key factors include:

- Low pressure: Results in lean mixtures and poor combustion.

- High pressure: Causes rich mixtures and potential flooding.

Inspect components like the fuel pressure regulator, fuel pump, and fuel pressure solenoid for faults.

7. Air Conditioning (A/C) Signal Issues

The A/C signal notifies the ECU to adjust idle speed when the compressor engages. If the signal is absent or faulty, idle speed may become excessively high or low, causing vibrations or stalling. Ensuring proper A/C signal function is critical for maintaining idle stability.

8. Exhaust Gas Recirculation (EGR) Valve Malfunctions

The EGR valve reduces nitrogen oxide emissions by recirculating exhaust gases. However, problems arise when:

- The valve sticks open.

- The valve doesn’t close properly during idle.

- Electrical faults occur in the EGR circuit.

These issues dilute the air-fuel mixture, resulting in rough idling or stalling.

9. Neutral Start Switch Circuit Problems

Vehicles with automatic transmissions rely on neutral start switches to adjust idle speed. Faulty signals from these switches can cause idle speeds to become excessively high or low. Diagnosing involves testing the switch and its circuit for continuity and accuracy.

10. Ignition System Faults

The ignition system plays a vital role in engine performance. Issues such as:

- Weak or no spark.

- Incorrect timing.

- Faulty ignition coils or high-voltage cables.

These faults can lead to misfires, weak combustion, and unstable idle performance.

11. Additional Factors

Other potential causes include:

- ECU malfunctions.

- Oxygen sensor or EFI relay circuit issues.

- Vacuum leaks in intake manifolds.

- Blocked air filters.

- Poor fuel quality.

- Low cylinder compression.

Comprehensive diagnostics often involve checking these secondary factors after eliminating more common issues.

Diagnostic Approach

When troubleshooting idle problems in EFI engines, follow a structured approach:

- Observe Symptoms: Identify specific idle issues, such as roughness or stalling.

- Scan for Error Codes: Use a diagnostic tool to retrieve fault codes from the ECU.

- Inspect Primary Components: Focus on common failure points like the idle switch, ISC valve, and injectors.

- Conduct Comparative Tests: Use technical data to benchmark component performance.

- Address Root Causes: Resolve identified faults methodically, starting with simpler issues.

Conclusion

Diagnosing idle issues in EFI engines requires a comprehensive understanding of the system’s components and their interactions. By systematically addressing common failure points, mechanics and enthusiasts can restore optimal engine performance efficiently. This guide serves as a reference for tackling such challenges, contributing to a smoother and more reliable driving experience.