Preparation and Initial Cleaning

Step 1: External Cleaning

- Immerse the injector in gasoline or cleaning solution

- Carefully remove external oil residue

- Wipe clean with a soft cloth

- Critical Check: Inspect rubber seals for damage

- Replace damaged seals immediately

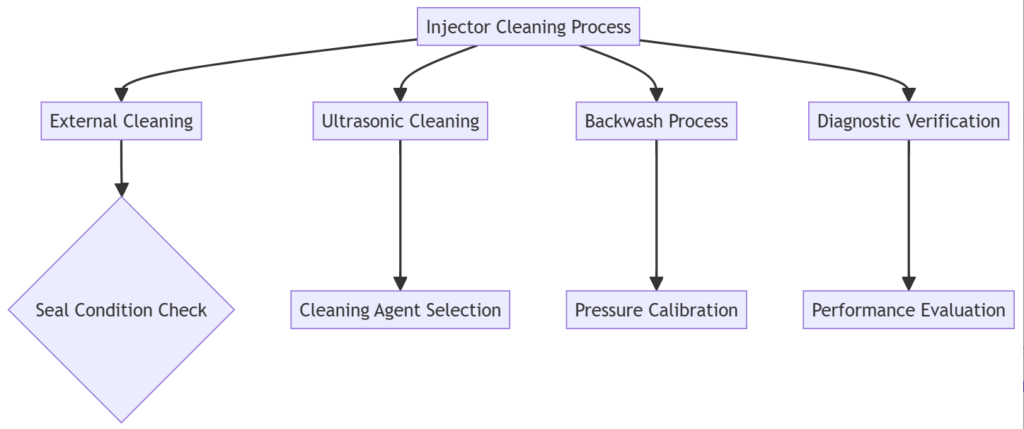

Professional Cleaning Process

Step 2: Ultrasonic Cleaning Setup

- Pour 2000mL of specialized injector cleaning agent into ultrasonic cleaning tank

- Install cleaning rack

- Place injectors on rack

- Ensure cleaning solution covers rack surface

Step 3: Ultrasonic Cleaning Parameters

- Power on ultrasonic cleaning machine

- Activate ultrasonic function

- Default cleaning time: 10 minutes

- Recommended setting: 600 seconds

Step 4: Backwash Process

- Connect backwash adapter to injector

- Mount on test rack

- Adjust oil pressure: 20-400 kPa

- Activate cleaning key

Step 5: Post-Cleaning Procedures

- Shut down oil pump

- Disconnect injector connection head

- Remove and separately handle seal rings

Detailed Cleaning Techniques

Carburetor Cleaning Method

- Use carburetor cleaning liquid

- Clean injector inlet and outlet carbon deposits

- Apply 12V voltage

- Connect cleaning solution via fine tube

- Use black tape to adjust tube diameter if needed

Cleaning Execution

- One person holds injector

- Another person intermittently activates 12V power

- Continue until spray mist is fine and uniform

Warning Signs of Injector Blockage

Performance Indicators

- Increased engine carbon deposits

- Delayed throttle response

- Sluggish acceleration

- Power reduction

- Increased fuel consumption

- Engine vibration

Precautionary Measures

Dos and Don’ts

- Avoid Aggressive Throttling

- Prevents further injector damage

- Reduces risk of complete injector failure

- Diagnostic Approach

- Identify root cause of blockage

- Prevent recurring issues

- Minimize unnecessary component replacement

Blockage Classification

- External Blockage

- Caused by ash and carbon deposits in combustion chamber

- Treatable with specialized cleaning agents

- Internal Blockage

- Resulted from fuel quality issues

- Requires targeted cleaning solutions

Recommended Cleaning Agents

- Use PNF-type additives

- Ensure high-quality, effective cleaning solutions

Key Recommendations

- Systematic diagnostic approach

- Professional cleaning techniques

- Regular maintenance

- Use high-quality fuel and additives

Technical Insights

Conclusion

Proper injector maintenance requires systematic approach, professional techniques, and understanding of underlying performance issues.

For professional-grade diesel injector cleaning equipment, visit DieselStart.com.