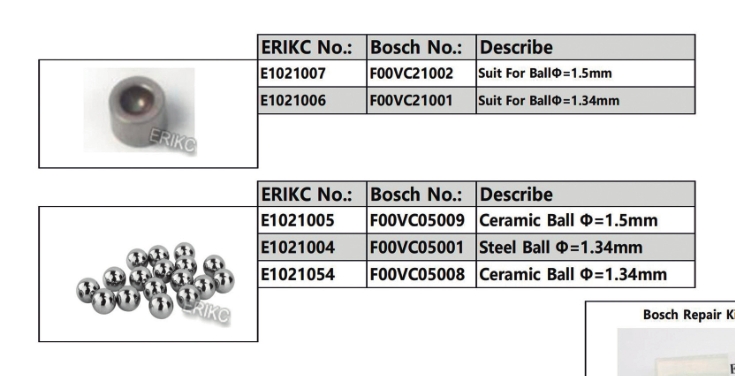

BOSCH Diesel Injector Ball Seat and Ball

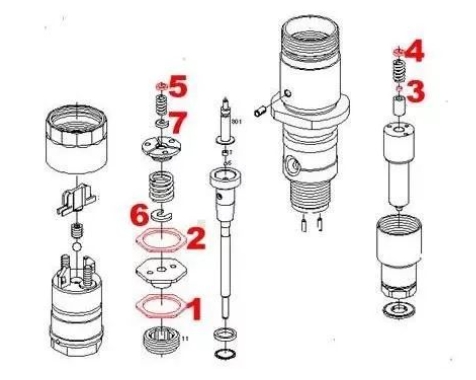

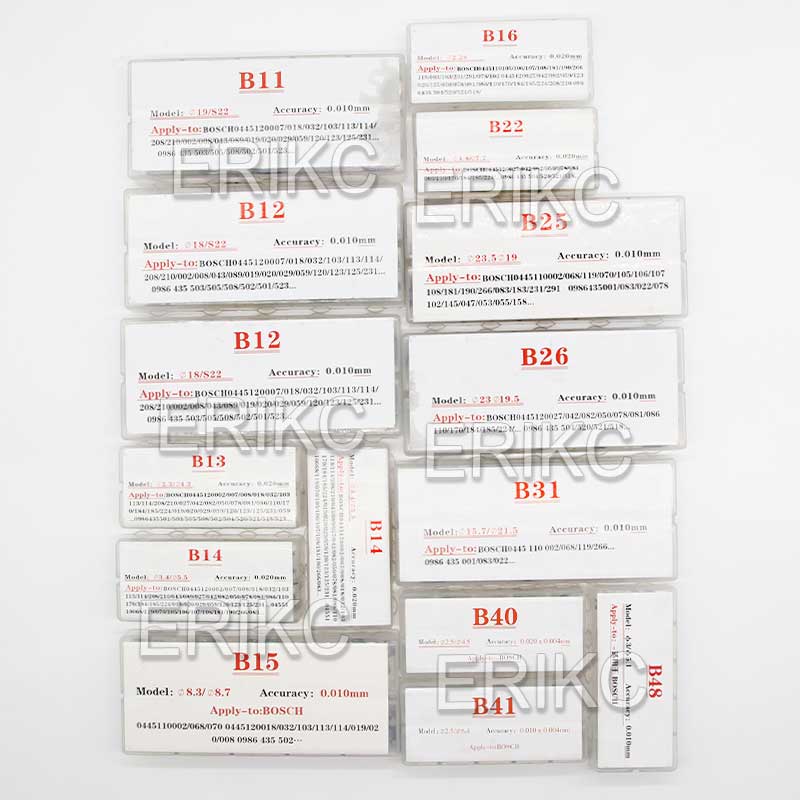

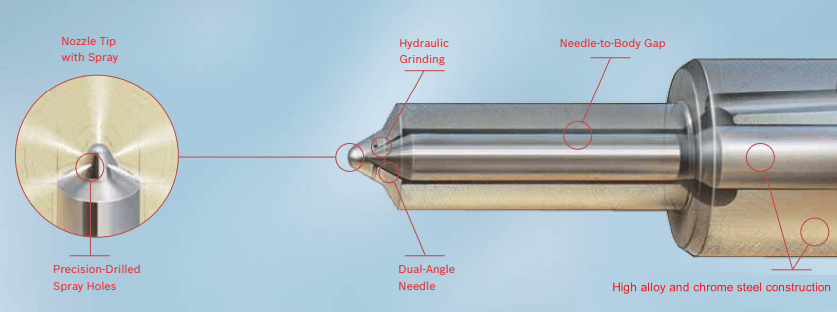

Replacing Bosch injector ball seats and balls depends on their condition and diagnostic results. These components control fuel flow in high-pressure systems and directly affect injector performance. Proper diagnosis using specialized tools is essential. If damaged or worn, replacement with OEM or compliant parts is recommended.