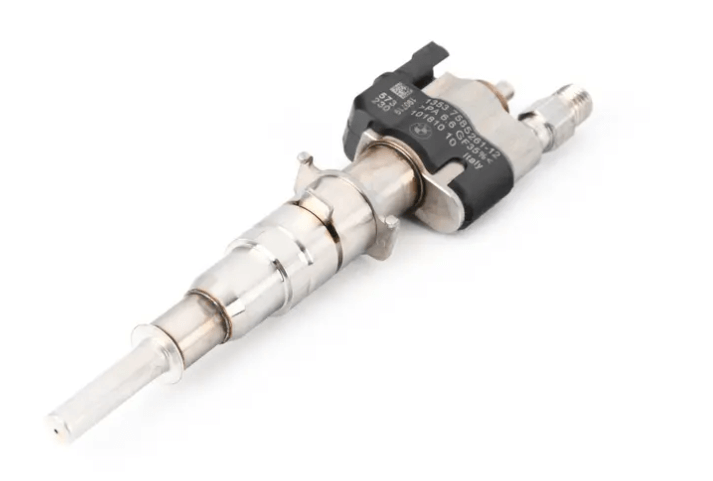

Bosch Common Rail Injector Repair Kits: F00VC99002 F00VC05009

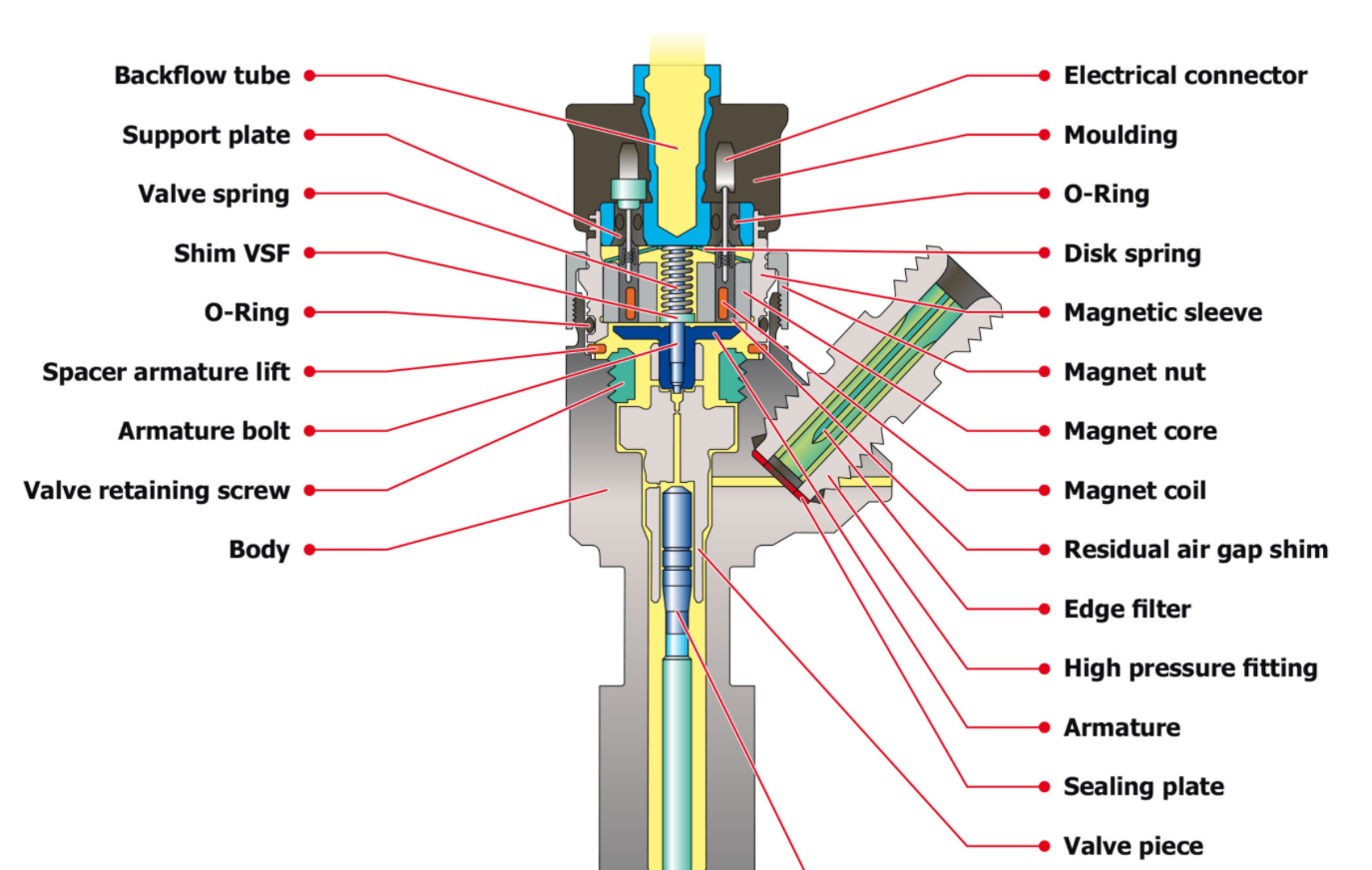

The Bosch F00VC99002 and F00VC05009 repair kits are essential for maintaining the performance and reliability of diesel common rail injectors, particularly Bosch 110-series models. These kits include a high-quality sealing ring, stability ring, and a precision ceramic ball (1.50mm diameter), ensuring accurate fuel injection and extended injector lifespan.