Ensure reliable and high-quality diesel injector repairs with our detailed, OEM-approved maintenance process. This comprehensive guide walks you through each essential step to tackle common injector repair challenges, including high failure rates and substandard parts. Our process includes:

Initial Inspection – Visual check and solenoid valve testing.

External Cleaning – Proper removal of O-rings and ultrasonic cleaning.

Quick Testing – Leak, return flow, and injection flow tests.

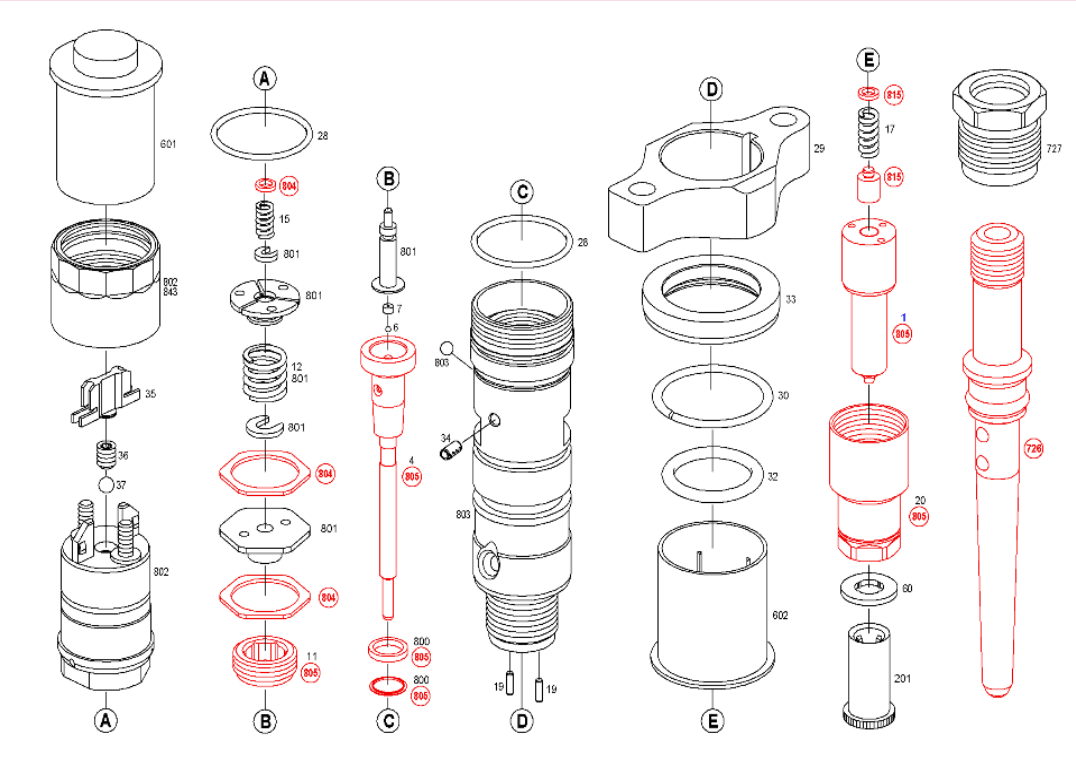

Disassembly – Safe removal of nozzle, solenoid valve, and other components.

Internal Parts Cleaning – Ultrasonic cleaning for thorough dirt removal.

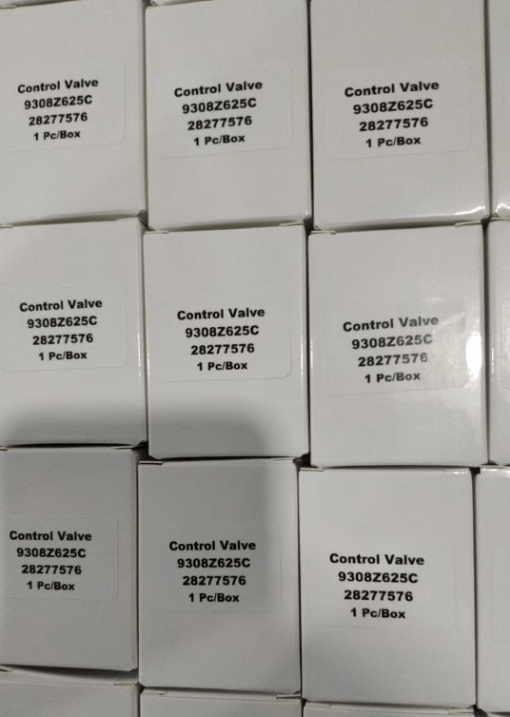

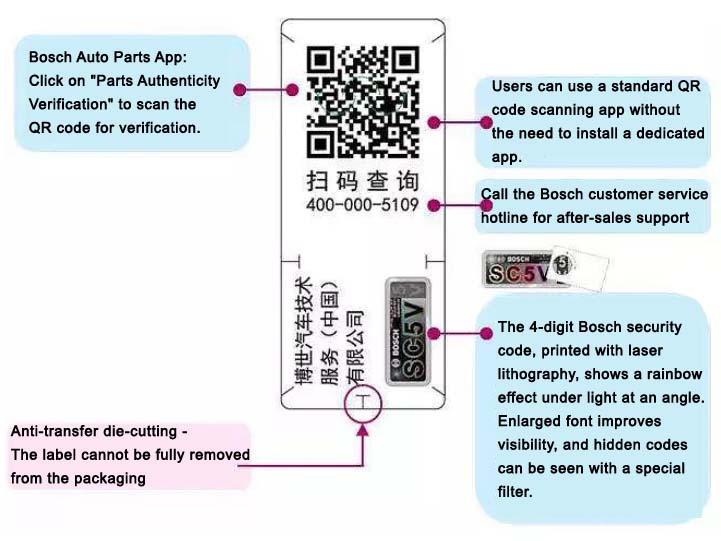

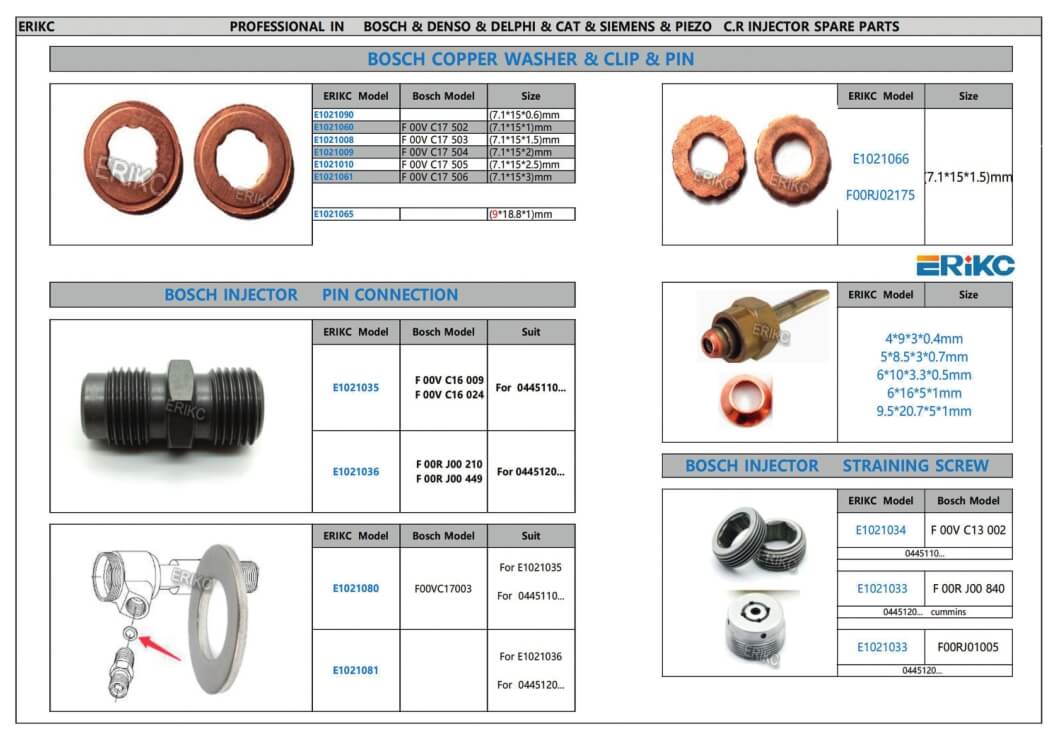

Parts Evaluation – Inspect and replace faulty parts with OEM-quality components.

Parts Assembly – Dust-free assembly with mechanical structure adjustments.

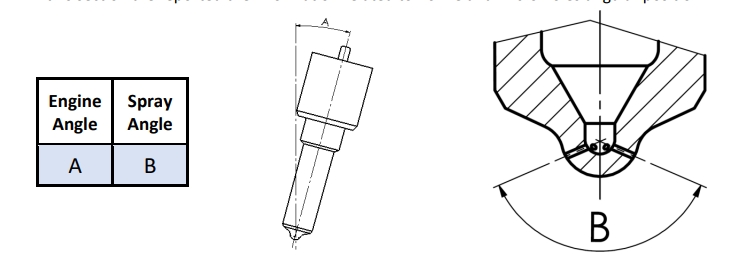

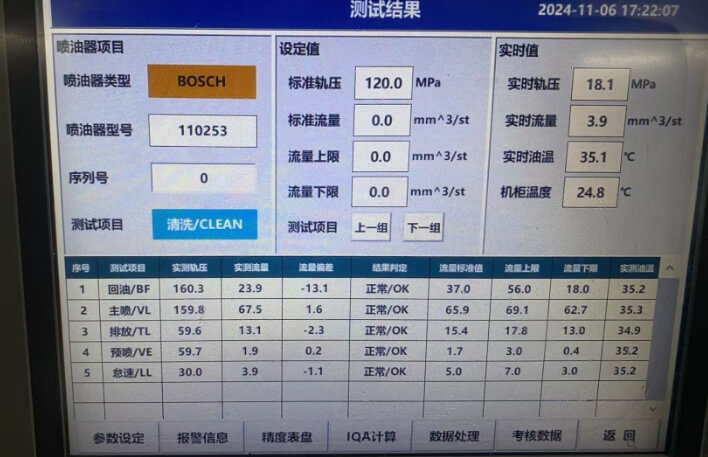

Injector Testing – Hydraulic performance tests with specialized tools.

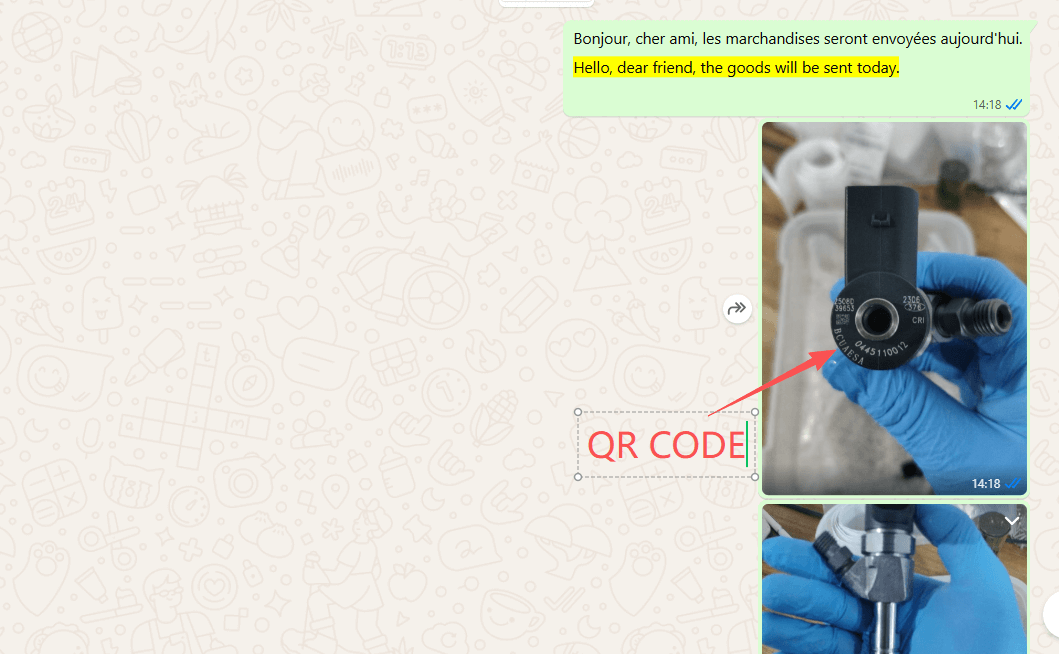

Packaging – Final checks before packaging.

On-Vehicle Testing – Real-world performance test before delivery.

Using advanced tools and OEM-quality parts ensures precision and longevity in your repairs, leading to improved customer satisfaction and reduced costs. Contact us today to upgrade your repair services!