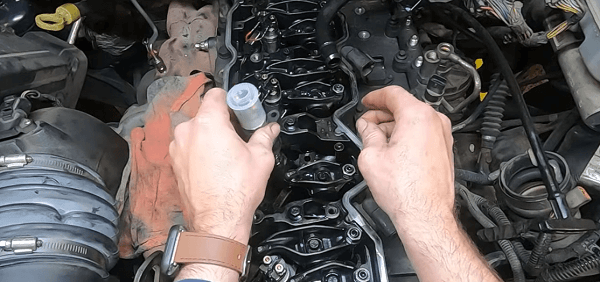

Explanation of Injector Fuel Quantity Correction – IQA Code

This article explores the Injector Quantity Adjustment (IQA) code — a vital correction value that fine-tunes diesel injector fuel delivery. Discover why IQA codes are essential, how they function, their effects on engine performance and emissions, and when programming is needed. Understanding IQA codes can help you optimize engine efficiency, reduce emissions, and ensure smoother diesel engine operation.